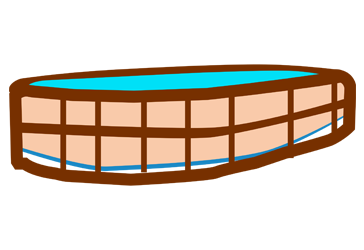

- Variety of options

- You can choose from a larger number of standard pools or have a pool completely tailor-made to your specific needs.

- Fast Installation

- Fast installation is a significant factor. Fibreglass pools are delivered and installed as a completed structure. That means your pool will be ready to swim in much sooner than a concrete pool, as the Installation can take as little as one week to complete with a fibreglass pool. You can luxuriate in your brand-new pool within two to three days after delivery.

- Minimal Maintenance

- Fibreglass pools require less maintenance than other pools. Fiberglass is also much easier to clean – think of the effort needed to scrub tile grout versus the smooth veneer of a bathtub. It has a smooth surface that almost maintains themselves, which keeps dirt from sticking to the floor and walls and also eliminates the risk of algae formation. Less algae means less chemicals, and therefore less maintenance. This also has a knock on effect on the amount of chemicals required to balance the water. Other pool alternatives can tear, whereas a fiberglass pool will maintain its flawless facade over time. This helps in a more enjoyable swimming experience.

- Long Lasting

- Like many material items, the amount one pays for it usually reflects the quality of the material and consequently how long it will last for. There are cheap options for Fibreglass pools, which are made from two or three layers of protection, and these will last on average 10yrs. Then there are the higher end fibreglass pools which have multiple layers, including reinforcement such as carbon ceramic. These types of fibreglass pools will outlive us all! Groundworks and the materials used for this will also add life to the fibreglass pool. Key tip: Only backfill using stabilised sand (14/1 sand/cement at 4% humidity) don’t let the pool builder convince you otherwise! And you can never have enough drainage! Exceptionally durable and damage resistant for normal day to day use, unlike liner pools that can be damaged by pets, branches, or rough use and can be costly to repair. Also modern fibreglass pools keep their good looks for longer thanks to advances in polyester rasins.

- Highest quality Fibreglass

- Hazel Pools fibreglass are manufactured to the highest quality standards. We check at the each stage of the swimming pool construction process, guarantee each one of our fibreglass pools are manufactured to the optimum strength and durability.

- Cost Efficient

- With the features discussed above, it is clear that – particularly on a higher end model – it would be money well spent. Coupled with the fact that far less electricity is required to run pumps and also fewer chemicals and maintenance costs are involved. If your fibreglass pool is heated, the higher quality Fibreglass pools have multiple layers which offer a high level of insulation, also come with inbuilt covers which can have solar heating slats or even insulated ones. All these features will reduce your demand for heating and thus save you electricity.

FEATURES OF FIBREGLASS POOLS

- Pool shells are manufactured to the highest standard for maximum durability and resistance to last a lifetime.

- Engineered to withstand all weather conditions.

- Have smoother surface which helps in keeping dirt from sticking and eliminate the risk of algae formation.

- Retain the heat better. Fibreglass is an insulating material. These features ensures that your water will always heat least 8°F warmer than any of other pool designs.

- Pool shells are flexible and adjust with ground conditions instead of cracking as concrete pools may.

- Simplified pool maintenance. It require less maintenance than conventional pools.

- Built-in features, Features built into the pool structure include steps, tanning shelves, ledges, lights and cleaning jets.

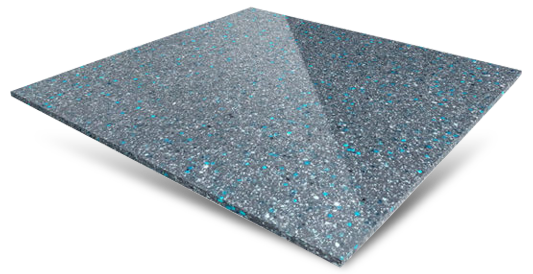

- Attractive finishes in a range of colour options, that are stain and chemical resistant.

- Available in a wide range of shapes, sizes and design options.

- Compatible with salt chlorinators. Salt chlorination has no adverse effects on pool structure, unlike other pools, which are prone to problems with salt.

- Pool shells are able to flex, accommodating temperature changes, natural earth movement and most earthquakes.

- Compared to other pools, fibreglass fluctuates less in temperature, plus assists with heat retention.

Color Options

The fibreglass pool color range allows your to stylize and customize your swimming pool. Choosing a color for your fibreglass pool, along with the design and water features, is an entertaining way to make your pool a spectacular reflection of your particular style.

Fiberglass is a combination of resin and glass fibers which creates a fiber reinforced plastic.

Fiberglass is made by adding resin to the glass fibers. Different resins can then be added to make the product stronger, tougher, and less brittle. Fiberglass can easily be molded into a variety of shapes and is incorporated into many industrial products due to its malleability and durability, including everything from equipment shelters to ducts to airplanes.

Fiberglass pools having beating record numbers for years. In most cases they’re now the first choice of anyone looking for a pool. This is due to all the advantages that polyester pools hold for the client.

Without doubt, the designs are increasingly spectacular and are more than a match for other types of pools. What’s more, the quick installation and peace of mind they offer are undoubtedly a major reason for choosing a polyester pool.

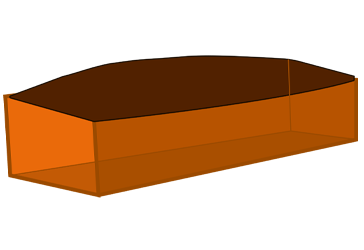

How fiber swimming pools are made ?

The pool pattern

The pool mold

Right side up

The pool mold

Upside down

It all starts with a mold. We build the pattern (or plug) of the pool from scratch out of wood. Once the wooden frame is built and the pool shape is set, we start building the mold inside of the pattern. We can use the mold to make hundreds of fiberglass swimming pools, each with the exact same shape and features.

To make a fiberglass swimming pool shell from a mold, we start by spraying the outside of the mold with the gelcoat layer. The gelcoat is the smooth surface of the pool that you see and touch.

Next, we apply a vinyl ester resin barrier coat. The vinyl ester resin (as opposed to polyester resin) creates a watertight barrier which prevents the gelcoat from forming bubbles (AKA osmotic blisters, a common problem with fiberglass pools).

The next layer uses chopped fiberglass and polyester resin. We only need one layer of vinyl ester resin to make the pool watertight, so we finish the rest of the pool shell with traditional polyester resin. We also layer on woven roving (woven glass fibers) onto stress points of the pool and apply structural honeycomb fiberglass in strategic areas to add even more strength.

Finally we spray on one last layer of fiberglass with polyester resin before we let the pool cure, remove it from the mold, trim the excess fiberglass from the edges, and perform our quality inspection.